CFRTP (Carbon Fiber Reinforced Thermo Plastic) composite material has many performance advantages, such as high modulus, high strength, light weight, low thermal expansion coefficient, high temperature resistance, easy welding, high recycling, etc., so it can be used in many fields to replace traditional steel, aluminum and other metal materials, and plays an very important role in the application of high-tech materials and industrial parts, such as medical equipment, aerospace technology, transportation, new energy industry.

The manufacturing process of this high-tech material is complex, the equipment manufacturing cost is large and the equipment requirements is high. The most critical is the complete CFRTP production line and stable after-sales service.

Unidirection Prepreg Tape Composite Extrusion Machine

CFRTP (Continuous Fiber Reinforced Thermoplastic composites) is based on thermoplastic resin as matrix and continuous fiber as reinforcement material, a new type of thermoplastic composite material with high strength, high rigidity, high toughness, and recyclable that is formed through resin melt impregnation, extrusion and other processes.

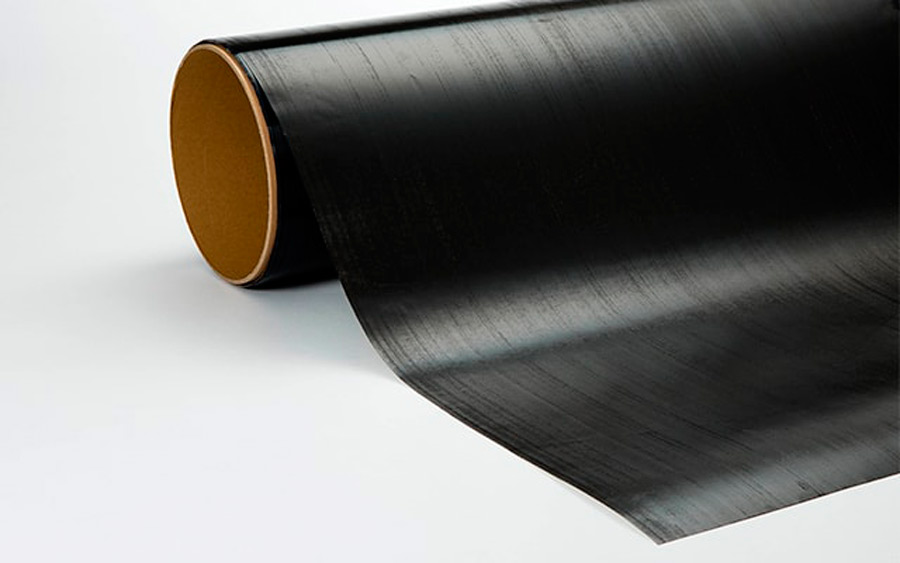

CFRTP-UD Unidirectional Tape: CFRT unidirectional tape is a single-layered, fiber-reinforced thermo plastic composite sheet in which the continuous fibers are unrolled and laid and impregnated with a thermoplastic resin. It is characterized by fibers arranged parallel to each other (0° direction) without interlacing. Product width 300-1500mm, can be customized.

① Basic resins: PP, PE, pet, pa6, PPS, peek, etc.

② Fiber type: glass fiber, carbon fiber, aramid fiber, basalt fiber and other high strength fibers.

③ Thickness of products: 0.1-0.45mm.

④ Product width: 50-1500mm.

⑤ Product surface density: 100-650gsm.

⑥ Fiber content of products: 40% - 70%.

⑦ Traction speed: 5-25m / min.

Introduction of CFRTP Plate Composite Extrusion Machine

CFRT thermoplastic laminate composite production line: The thermoplastic composite board prepared by continuous fiber reinforced tape through a special process has excellent mechanical and physical properties. The overall density of the plate is only 1/5 of the steel plate and 1/2 of the aluminum plate.

Production process of CFRTP Material Extrusion Line

The pressure is transmitted by the upper and lower conveyor belts and the contact heating and cooling systems are integrated. The composite material will be heated evenly, and the material will be cooled before leaving the upper and lower belts. Different heating zones and cooling are combined according to different process requirements. The length of the zone and the number of pressing rollers, by controlling the temperature, speed and pressure, the material will be perfectly attached and have a good bond. The upper and lower belts have a uniform gap and precise spacing adjustment to ensure that the surface composite material is flat and wrinkle-free. To achieve continuous work.