Our Main Chemical Fiber Spinning Machine Service is As Follows:

Melt direct spinning project turnkey project.

Polyester, nylon, composite POY spinning engineering complete sets of equipment.

Polyester bottle flake spinning engineering complete equipment.

Polyester/nylon/composite FDY spinning engineering complete equipment.

BCF carpet yarn spinning production line.

Polypropylene FDY spinning production line.

Industrial yarn technology and complete spinning equipment.

Melt-spun spandex spinning complete equipment.

Special fiber and composite new material spinning complete equipment.

Engineering transformation of spinning project.

Various spinning equipment parts (extruder, winding head, hot roller).

Monofilament spinning engineering complete equipment.

PET-POY High Speed Spinning Machines Series

This machine is mainly used for spinning 30-330dtex polyester POY and adopts LTM type pin screw, domestic-made continuous melt CPF, thus extend the service life of spin packs. Both top-mounted and bottom-mounted high-pressure rectangular and cup-shaped spin packs are available. Unique planetary spinning pump and separately driving finish oil pump. Individually controlled, imported inverter and components.

New adjustment GR, imported inverter and components.

PA6-POY/FDY High Speed Spinning Machines Series

This machine is mainly used for chips spinning of PA6 and PA66. Adopt new type of bimetal, barrel and special manifold design. Energy saving spin beam, equipped with botton mounted, high pressure cylinder spin pack. Unique planetary spinning pump and separately driving finish oil pump. With well designed air suctivice for monomer.

Uniform front dismountable quenching chamber and unique nozzle type oil adding device. Equipped with precision winding and high speed automatic winders, high succssfully of doffing, fineless of yarn shape, and good function of unwinding.

PET+Carpet Special Fiber-Mainly Suitable for Fifinal Specifification 300-600D

The new spin beam melt pipe design adopts an energy-saving spin beam and is equipped with a bottom-mounted high-pressure self-sealing cup-shaped component. The new single-component design improves the output, the new side blowing design has a more uniform wind speed, and the front-removable, unique nozzle-type oiling device can meet the requirements of thick carpet yarns in various countries.

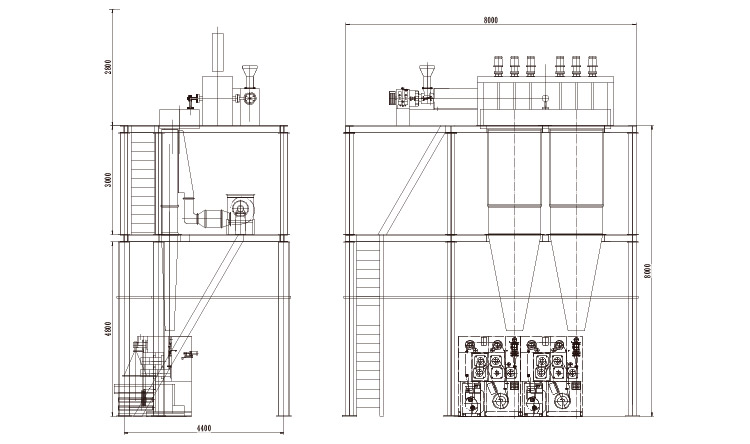

Auxiliary equipment:

The conveying system, crystallization drying system, air conditioning system and

cooling system ensure the quality of spinning project.Automated process operations.