The whole solution includes HDPE Fishing Raft pedal extrusion line, marine floating bucket blow moulding machine and marine pipe extrusion line, which is the trend of marine aquaculture in the future. This product has a series of advantages, such as green environment protection, recyclability, typhoon resistance, anti-aging, anti-ultraviolet ray and so on. It ensures the marine ecological environment from being destroyed. It has been promoted abroad. China coastal aquaculture areas are gradually popularizing.

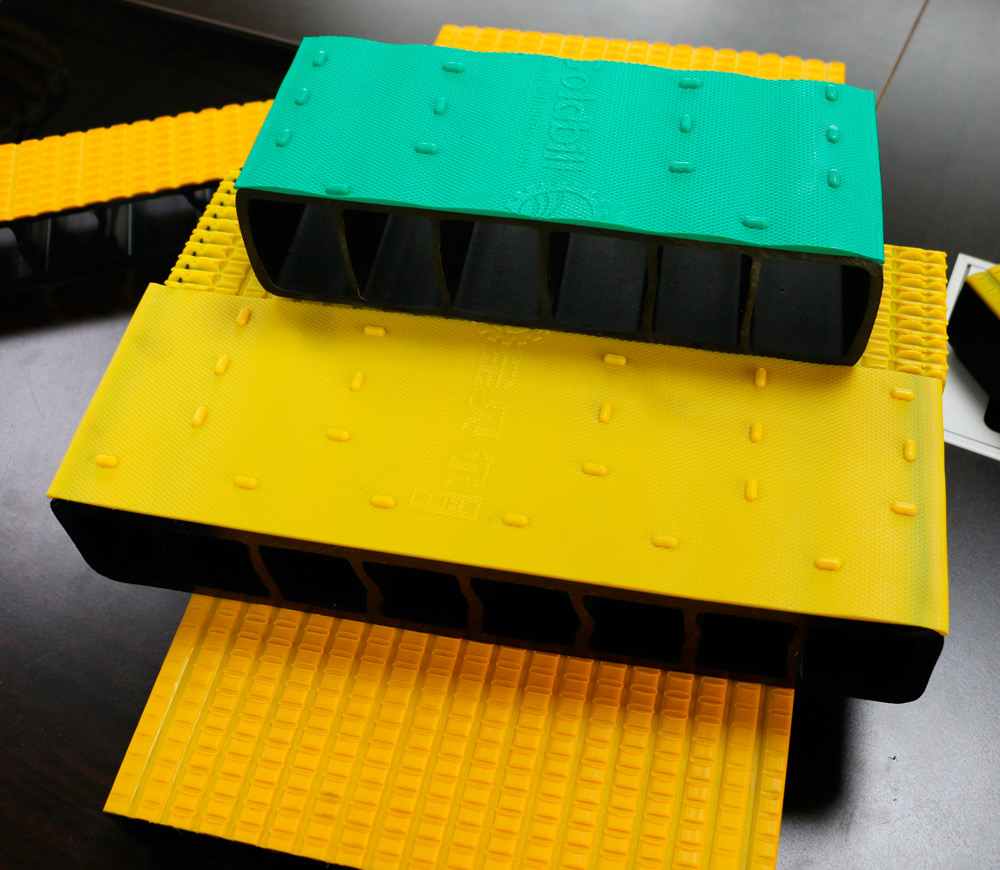

Introduction of HDPE Marine Pedal Extrusion Line

This production line adopts latest HDPE extrusion technology with special designed screw for excellent plasticizing and accurate vacuum&temperature system for good product shape and strong hardness. We have professional at various plastic extrusion equipment with over 25 years experience and have ranked No.1 in the extrusion industry for 11 consecutive years in China market, which means we have enough resource and strength to provide you high quality machines and reliable service.

Technical parameter

| Model | Product width | Type | Power of main motor | Output |

| JWS75/33+JWS45/33 | 300-400mm | YF400 | 75KW+30KW | 250-350 |

| JWS90/33+JWS45/33 | 500mm | YF500 | 110KW+30KW | 400-500 |

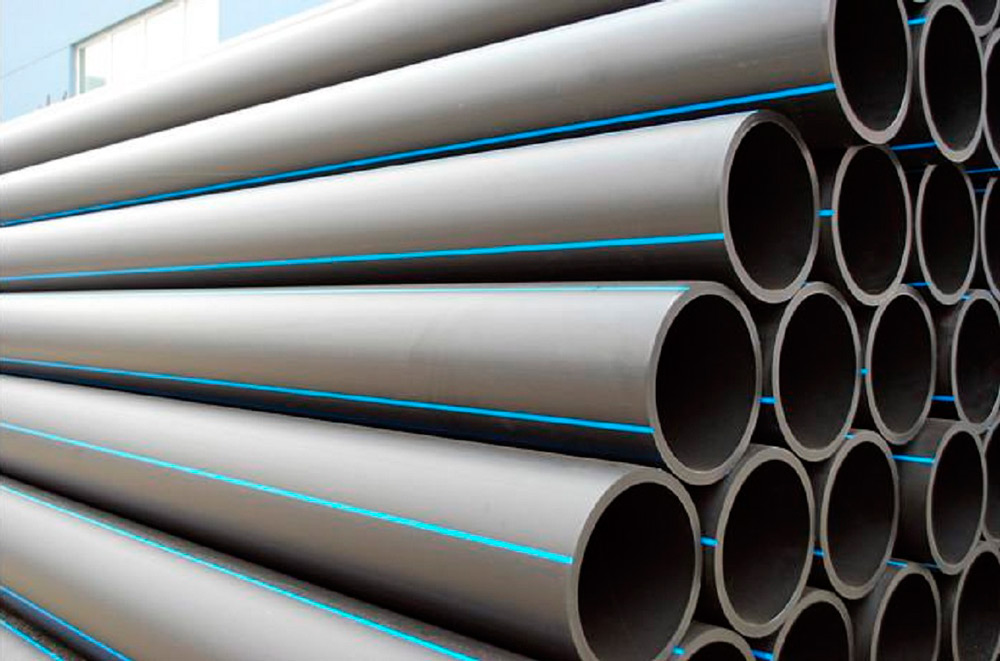

Introduction of HDPE Marine Pipe Extrusion Line

This production line adopts the most advanced technology of Europe, which is suitable for high speed extrusion of HDPE pipes and other plastic pipes. Compared with common production line, reduce to 35% energy, and the product efficiency increase more than 1 time, thus it is not only saving the cost of site and manpower but also improving efficiency. This production line has nice appearance, higher output, stable production and reliable after-sales service.

Technical parameter

| Type | Pipe spec (mm) | Extruder | Max.output (kg/h) | Total power (kw) |

| JWGXPE-63 | Φ20-Φ63(double) | JWSGX60/38 | 450 | 207 |

| JWGXPE-250 | Φ50-Φ250 | JWSGX75/38 | 650 | 280 |

| JWGXPE-400 | Φ110-Φ400 | JWSGX75/38 | 650 | 340 |

| JWGXPE-630 | Φ315-Φ630 | JWSGX90/38 | 1000 | 466

|

Introduction of Marine Floating Bucket Blow Moulding Machine

This blow moulding machine is suitable for producing different size bucket, and adopts high quality die head, up-blowing structure, scrap conveying on line, finished product leak testing on line, conveying, packing and others, which highly reduce the working cost and increasing the production efficiency.

Technical parameter

| Model | Unit | BM30F | BM160F | BM230F |

| Die head structure | Accumulating type |

| Main screw diameter | mm | 80/25 | 120/30 | 120/32 |

| Max plasticizing capacity (PE) | kg/h | 110 | 280 | 350 |

| Driving motor | Kw | 37 | 90 | 132 |

| Accumulating volume | L | 5.2 | 28 | 32 |

| Oil pump motor power | Kw | 22 | 30 | 37 |

| Clamping force | KN | 280 | 800 | 900 |

| Space between platen | mm | 350-800 | 500-1400 | 800-1800 |

| Platen size W*H | mm | 740*740 | 1120*1200 | 1320*1600 |

| Max.mould size | mm | 550*800 | 900*1450 | 1200*1800 |

| Heating power of die head | Kw | 15 | 30 | 36 |

| Machine dimension L*W*H | m | 4.3*2.2*3.5 | 7.6*4.4*5.5 | 8.6*4.6*6 |

| Machine weight | T | 12 | 20 | 36 |

| Total power | Kw | 95 | 172 | 230 |