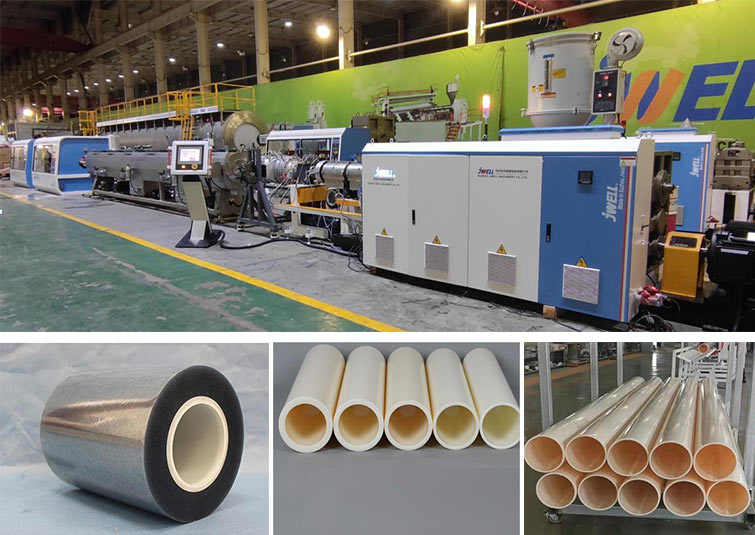

According to different application, we provide different types of extrusion lines for processing PE, PP, ABS material with professional technical proposal.

Complete production process: Automatic drying feeder, JWS90/38 single screw extruder, Metering pump, Mold, Vacuum calibration table, Haul off machine, Chipless cutting, PLC control system.

The Market Requirements for Film Core Tubes are as Follows:

1. Uniform thickness, smooth surface of inside and outside, good straightness

2. The cutting length is required to be accurate (most of them are offline slitting)

3. Precise chamfering

4. High output, energy saving

Technical Parameter of PE, PP, ABS Film Roll Core Tube Extrusion Line

| Model | Pipe Spec (mm) | Extruder | Main Power (kw) | Output (kg/h) |

| JWPEG-H63 | Φ16-Φ63 | JWS-H 60/40 | 90 | 400 |

| JWPEG-H110 | Φ20-Φ110 | JWS-H 60/40 | 110 | 450 |

| JWPEG-H160 | Φ50-Φ160 | JWS-H75/38 | 132 | 500 |

| JWPEG-H250 | Φ75-Φ250 | JWS-H75/38 | 160 | 650 |

| JWPEG-H315 | Φ110-Φ315 | JWS-H75/38 | 160 | 700 |

| JWPEG-H450 | Φ16O-Φ450 | JWS-H 90/38 | 250 | 950 |

| JWPEG-H630 | Φ315-Φ630 | JWS-H 90/38 | 280 | 1050 |