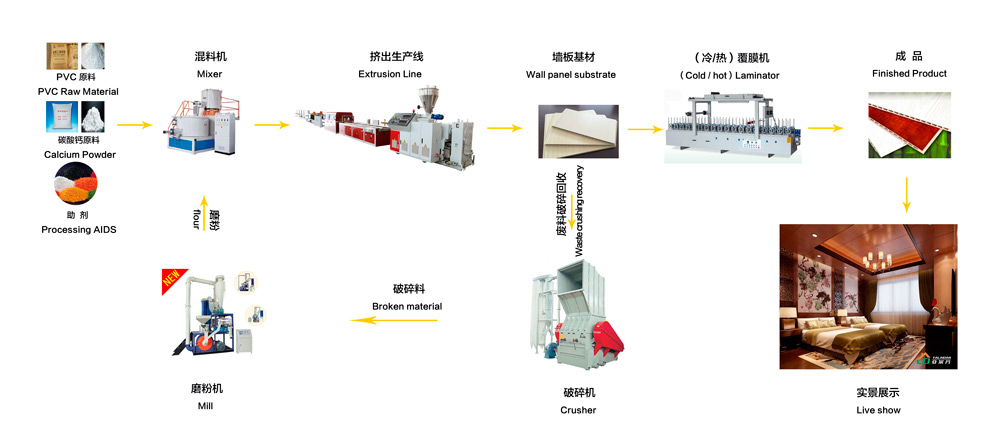

The full PVC wall panel extrusion line based on famous brand PLC control system includes mixer, feeding unit, twin screw extruder, mold, calibration unit, haul off unit, cutting unit, film covering unit, stacker, crusher and pulverizer. Before shipment, each PVC wall panel extrusion machine will undergo strict testing and qualified commissioning.

PVC Wall Panel Extrusion Machine Specification

High speed main technical parameter of pvc wall panel extrusion line

| Type | YF240 | YF240 | YF240A |

| Max. width of product (mm) | 240 | 240 | 150*2 |

| Extruder model | SJP75/28 | SJP93/30 | SJP110/28 |

| Max.extrusion capacity (kg/h) | 150-250 | 250-400 | 400-500 |

| Extruder power (kW) | 45 | 55 | 90 |

| Cooling water (m3/h) | 7 | 8 | 10 |

| Compressed air (m3/min) | 0.6 | 0.6 | 0.8 |

Classic type main technical parameter of pvc wall panel extrusion line

| Type | YF108 | YF240 | YF240A | YF300 | YF400 |

| Max. width of product (mm) | 108 | 240 | 150*2 | 300 | 400 |

| Extruder model | SJZ55/110 | SJZ65/132 | SJZ65/132 | SJZ65/132 | SJZ80/156 |

| Max.extrusion capacity (kg/h) | 150 | 250 | 250 | 250 | 450 |

| Extruder power (kW) | 22 | 37 | 37 | 37 | 55 |

| Cooling water (m3/h) | 7 | 8 | 8 | 8 | 10 |

| Compressed air (m3/min) | 0.6 | 0.6 | 0.8 | 0.6 | 0.6 |