The XPE foamed sheet production line is a mature production line designed by Jwell Machinery Co., Ltd. based on 20 years of experience in screw design and continuous optimization. XPE special extruder unit, relying on the company's years of experience in screws, optimizes the structure design of the screw on the basis of the conventional XPE extruder screw, improves the cooling system of the barrel and screw core, and also carries out the structural dimensions of the mold. Larger changes make the extruder and die work well under the condition of high screw rotation speed to ensure the plasticization of the material, uniform dispersion, and temperature controllable.

The new three-stage extended furnace is 23 meters long and 5.5 meters high. It is divided into preheating section, cross-linking section and foaming section. Equipped with imported brand-name high-precision energy-saving burners to ensure that the temperature of each section is controlled within plus or minus 1 degree. Meet the foaming process requirements. The furnace body is a three-stage furnace with the same amount of working gas as a two-stage furnace. Can produce XPE, IXPE rubber and plastic foam products. XPE (IXPE) is a free-style continuous foaming material. Smooth surface, closed cell, independent, uniform, non-absorbent, unlimited length, non-absorbent soft material. The biggest feature of this furnace is its large output, with a maximum of 200~220 kg/h

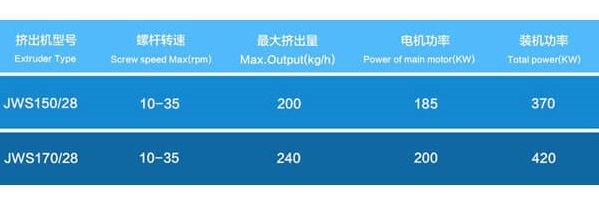

Specification of XPE Foam Sheet Extrusion Line

XPE Foaming Furnace Performance Advantages

1) The preheating and cross-linking sections have been greatly changed to reduce the heat capacity space while meeting the process requirements. At the same time, energy is saved.

2) The heat distribution in the furnace overcomes the defect of unreasonable heat distribution in the furnace in South Korea, and is closer to the working heat requirement of XPE foaming. Make XPE foam in a relatively wide process range, foam fully and stable.

3) Large output. Among the foaming furnaces currently produced in China, our three-stage furnace has the largest output (maximum 200 kg/hour or more). In addition, XPE foam cells are denser than two-stage furnaces. The gas consumption is equivalent to that of a two-stage furnace.

4) Observation holes are set on the wall panels of the foaming section. At the same time, a baffle structure is set at the exit of the foaming furnace, and the size of the furnace mouth is adjusted according to the production conditions, so as to achieve the effect of energy saving.

5) The maximum expansion ratio can reach 35-40 times.

XPE Sheet Application

XPE sheet is applied in Ideal materials for heat preservation of automobiles and air conditioners have developed rapidly in the sports and leisure goods market in recent years, such as surfboards, moisture-proof mats, yoga mats and so on. It also has certain uses in construction, and it has a wider range of applications in flame retardant materials. In recent years, it has been widely used in the automotive and packaging industries.

The Characteristics of XPE Foam Material

Its structure is an independent closed-cell material, so it also has the function of heat insulation and heat preservation; it also has the characteristics of reducing noise and waterproofing, and it has heat resistance, aging resistance, and chemical resistance. In particular, it meets the excellent characteristics of international environmental protection requirements and the product itself is coiled and can be laminated, so cross-linked polyethylene foamed coils are widely used in: central air-conditioning engineering, pipeline engineering, large containers, high-grade composite roofing (insulation Sound insulation) system; conductive packaging of luggage lining, integrated circuit board and other electrical appliances; midsole of high-end sports shoes; automotive cushioning and thermal insulation, decorative materials; floating materials; single-layer or double-coated tape products and other fields.

Radiation cross-linked foamed sheet (IXPE for short): The surface of this chemically cross-linked foamed sheet is more stable, dense, with smaller and more uniform cells, and all physical properties are better than XPE. It is widely used in construction and chemical engineering. Pipeline, thermal engineering, vehicle and ship manufacturing, packaging industry, agriculture, fishery, sports and entertainment industries. At present, this product is still in the growth stage of the market in Mainland China, and the potential for development is quite large. The IXPE whole plant equipment manufactured by Jinwei Company mainly includes three parts: extrusion pelletizing, extruding sheet, and foaming production line.