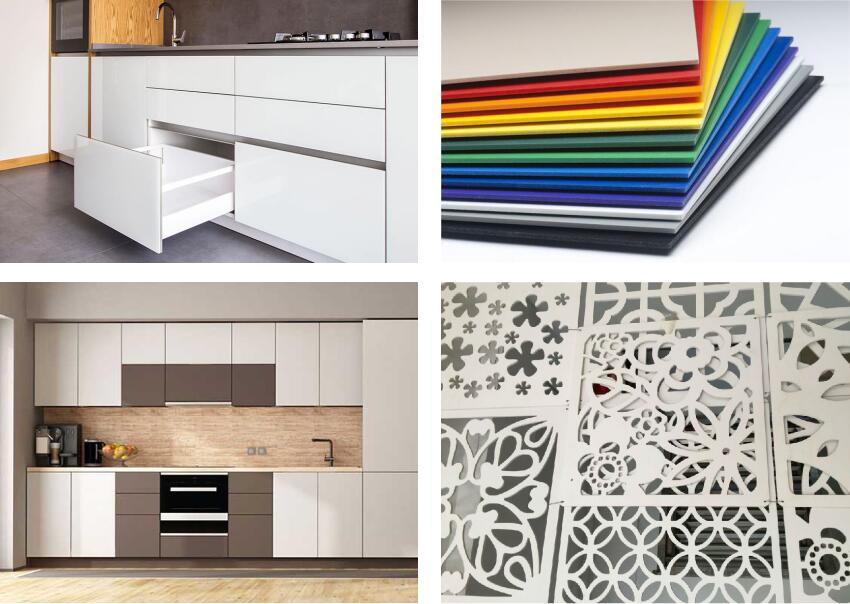

We export over 3000 sets full plastic profile extrusion production lines to many countries every year. This PVC skinning foam board extrusion line is still running perfectly at our customer factory in Egypt, who purchased last year, and they are going to order another lines from us. They produce single layer PVC foam boards and multi-layer foam boards which are used for indoor wall decoration panels and outdoor advertisement boards. The PVC foam boards produced by them has the advantages of uniform thickness, same width, smooth surface and good physical performance.

Besides, jwell extruder also has exported many PVC window door profile extrusion lines to Egypt, Algeria, India, Bangladesh and Pakistan. We have won a lot of praise and support with reliable equipment and high-quality service.

Why they choose Jwell PVC skinning foam board extrusion line?

The production of this extrusion line has the features of precise temperature control device, computer PLC operation system and high output with low energy consumption.

The surface hardness of the product is between the skinning foam board and free foam board.

The investment of this machine is low and our production line has long service life based on high hardness frame and high quality mechanical parts.

The technical specification of our PVC foam board extrusion line is based on practical situation, production requirements and future planning of our customers.

In view of the customer's inexperience, we arranged a professional commissioning engineer to their factory to help them how to operate and install the full production line and teach their workers how to deal with small problems of the machine.